Spray Nozzle Engineering is a major distributor of Lafferty’s broad array of Foamers, Sanitisers, Sprayers, Mixing (Proportioning) Stations, Foggers, Asphalt Release Systems, and cross-contamination control systems. Our professional staff can assist you in selecting the best Lafferty Equipment to decrease chemical consumption and waste, which is healthier for the environment and your profitability! You can rely on Lafferty Equipment’s 40+ years of experience for performance.

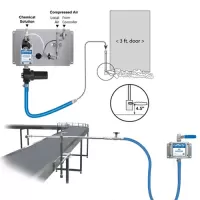

Lafferty products are available in a variety of pressure and volume settings to meet your needs. The majority of items are available in both portable and wall mount configurations.