- Patented orifice insert system

- Mechanically assembled, no adhesive construction

- Longer life and pressure range

- Optional filter screens for all pipe sizes

Ruby Trim Needle Jet Nozzles

The Ruby Trim Needle Jet Nozzles features the Patented Orifice Insert System

Spray Nozzle Engineering has developed a patented Orifice Insert System on all Ruby nozzles. This mechanical sealing method does not rely on outdated adhesive anchors; reducing the risk of premature orifice dislodgement resulting from water hammer, line shock or cleaning operations.

Standard orifice materials available:– RUB – Ruby.

Characteristics

High Impact needle jet (0º spray angle) available in two body configurations (Flat and angle).

Applications

Trim squirt or deckle cutting in pulp and paper mills, process equipment or when a high impact and hard wearing needle jet is required.

Materials

316 stainless steel body complete with a high grade Ruby insert.

Threads

1/8″ BSP or NPT pencil and protected body nozzles (Adaptors available on request).

Air shield system – Patented Orifice Insert System on ruby nozzles

The air shield system introduces a concentric shield of compressed air around the nozzle tip whilst spraying, reducing build up on nozzle orifice and maintaining laminar flow of needle jet pattern.

Visit our pulp and paper nozzle gallery

Performance Information

| Orifice (mm) | Thread Size | Flow Rate Litres/Min @ Bar G | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/8″ Flat | 1/8″ Angle | 3 | 6 | 10 | 15 | 20 | 30 | 50 | |

| 0.4 | RUBS | RUBT | 0.16 | 0.22 | 0.35 | 0.39 | 0.39 | 0.53 | 0.8 |

| 0.5 | RUBS | RUBT | 0.27 | 0.36 | 0.52 | 0.61 | 0.61 | 0.79 | 0.96 |

| 0.6 | RUBS | RUBT | 0.38 | 0.55 | 0.72 | 0.78 | 0.78 | 0.83 | 1.20 |

| 0.7 | RUBS | RUBT | 0.56 | 0.71 | 0.90 | 0.95 | 0.95 | 1.08 | 1.40 |

| 0.8 | RUBS | RUBT | 0.59 | 0.82 | 1.30 | 1.50 | 1.50 | 1.80 | 2.00 |

| 0.9 | RUBS | RUBT | 0.78 | 1.10 | 1.60 | 2.00 | 2.00 | 2.50 | 3.10 |

| 1.0 | RUBS | RUBT | 1.20 | 1.60 | 2.40 | 3.10 | 3.10 | 3.80 | 4.70 |

| 1.2 | RUBS | RUBT | 1.40 | 2.00 | 2.90 | 3.60 | 3.60 | 4.00 | 5.80 |

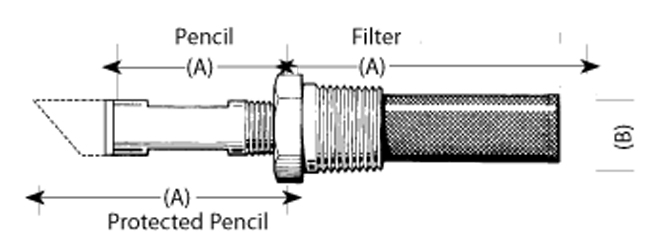

| Body Type | Approx. Dimensions (mm) | Weight (gms) | |

|---|---|---|---|

| 1/8″ Protected Ruby Only (RUBT) | 46.9 | 10.5 | 13 |

| 1/8″ Pencil Ruby Only (RUBS) | 35 | 10.5 | 12 |

| Standard Filter for Pencil | 50.5 | 17.5 | 25 |