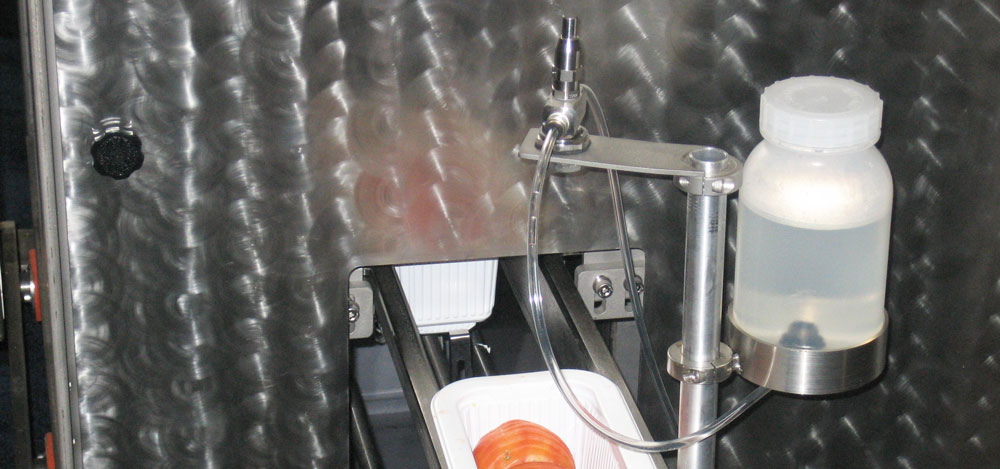

Industries throughout Australia use air atomising nozzles for a variety of applications. Any application that requires a misting spray or a low and steady flow rate works well with this equipment. Coating, glazing and humidifying areas are three popular uses. It’s also not uncommon to see air atomising nozzles used in precision glazing or coating applications like chocolate candy coating or egg glazing.

Understanding Why Air Atomising Nozzles Work for Precision Applications

Air atomising nozzles give a neat and even coating on whatever they spray, especially if the products move through the spray on a conveyor belt at a steady pace. A flat fan spray pattern evenly coats the items as long as the conveyor belt moves at a steady pace. For operations that start and stop, using full cone air spray pattern would provide even coverage for the products.

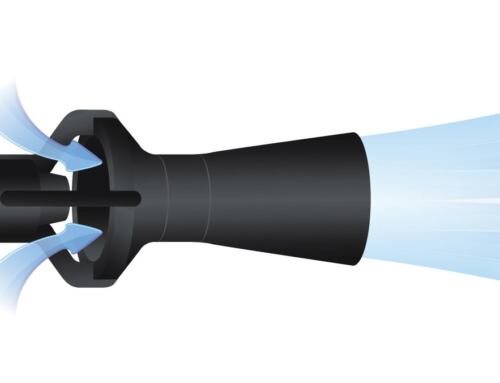

The XA air atomising nozzle system breaks up the fluid into tiny particles before spraying it using a stream of compressed air. The liquid and air stream mix before exiting the nozzle head in either a full cone or flat fan spray pattern. Air atomising nozzles use low flow rates, and you’re able to set them at a few different angles. All of these factors combine to give uniform coverage and precise control.

The XA 10 and 11 bodies attach to these industrial nozzles. The system allows for up to three cycles per second, and it contains an internal air cylinder that controls the spray’s pressure level. The XA nozzles come with several custom materials that allow you to customise your setup to fit your industry needs. They utilise an on/off operation and work well with standard and specialised application processes.

Uses for Air Atomising Nozzles

Several different industries utilise air atomising nozzles. The primary industries that have embraced air atomising nozzles include construction, chemical processing, beverage, food, pulp and paper, sanitisation and wineries.

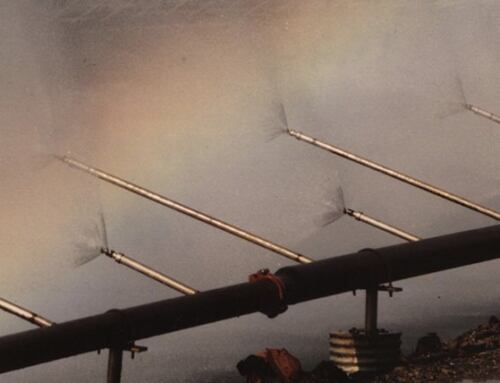

One company that specialises in wine storage commissioned an air atomising nozzle system. They wanted to keep their interior temperature and humidity levels consistent because this allowed them to age their wine correctly. They requested a nozzle control bank that they could use for their humidity control system. Once they installed it, they calibrated the system to deliver the correct amount of water to maintain consistent temperature and humidity levels.

In another example, a large construction supply company requested a new system compromising air atomising nozzles. They wanted to upgrade their current system to a complete spray system. A local control systems specialist collaborated with the company for the duration of the project, and the company commissioned a wall-mounted Bete XA 00 F’SS’ system. The system came with automatic 4×4 nozzle bank configurations that assisted the company in maintaining a precise humidity level. It accomplished this by delivering the exact amount of water needed to prevent humidity fluctuations.

Although these are more well-known uses for air atomising nozzles, you can find them in so many more applications. Wherever you need a misting spray nozzle, low flow rate or an atomising spray nozzle, this system works well. A few other popular uses include:

- Climate control

- Dust control

- Gas cooling

- Moistening

- Odour control

Air Atomising Nozzles Work with High Viscosity Fluids

Along with low viscosity fluids, air atomising nozzles are capable of creating even sprays with high viscosity fluids up to 100+ centipoise (cP). The Bete XAER uses low flow rates to produce a full cone round spray for even coverage. The system releases tiny particles that provide even and adequate high viscosity fluid coverage. You won’t get thick layers, uneven spots or clumps when you use this system on your products. Also, this rounded spray pattern goes hand in hand with the flat fan spray pattern the XAEF nozzle produces.

High viscosity air atomising nozzles feature an external mixing system, unlike the low viscosity fluid air atomising nozzle’s internal mixing system. Liquid atomisation will happen outside of the nozzle, and pressurised air doesn’t determine your fluid flow rate. This lower rate gives you better control each time you use it.

This system comes in ⅛ and ¼ nickel-plated brass or 303 or 316 stainless steel piping. If you have more demanding applications, you can request the nozzle system to be made out of a different material to help withstand wear and tear or corrosion.

The high viscosity fluid nozzle system comes with unique features that include:

- Narrow spray angles (10° to 30°)

- Precision liquid flow rate metering

- External mixing system

- Variable atomisation

- Round spray pattern for high viscosity fluids

- The liquid pressure controls your liquid flow rate instead of air pressure.

Coating foodstuffs and gas cooling are two applications that need air atomising nozzles with the capability of spraying high viscosity fluids. Spray drying is another use.

Contact Spray Nozzle Engineering to Buy Air Atomising Nozzles or for Technical Assistance!

At Spray Nozzle Engineering, we stock a wide range of air atomising nozzles. You can browse our stock and pick out your new setup, or you can contact us with questions today!