Improved spray drying, powder quality and cleaning hygiene with Click&Dry spray dry nozzle

The increased production of Milk Powder for Infant Formula is placing ever increasing demand on powder quality and the need for higher levels of cleaning efficiency and hygiene in plants. The spray dry nozzle used, plays a critical role in achieving these gains.

The increased production of Milk Powder for Infant Formula is placing ever increasing demand on powder quality and the need for higher levels of cleaning efficiency and hygiene in plants. The spray dry nozzle used, plays a critical role in achieving these gains.

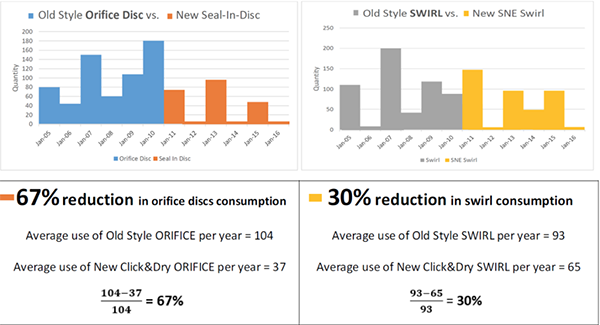

To achieve gains in this process, the Spray Dry nozzles offered by Spray Nozzle Engineering, provide improved performance whilst being easy to clean.

CLICK&DRYTM Nozzles have made cleaning and hygiene easier.

The CLICK&DRYTM Spray Dry Nozzle system is designed with improved cleaning and maintenance in mind.

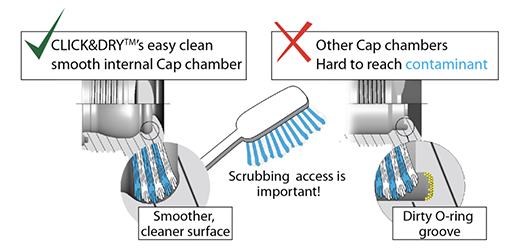

With its Smooth Cap Chamber Technology, all CLICK&DRYTM Spray Dry Nozzle Caps do not use O-Ring sealing grooves that can harbour contaminants.

Hygiene is improved with a totally smooth and easy to clean cap chamber design. Engineers at Spray Nozzle Engineering have perfected CLICK&DRYTM spray dry series to address all areas of performance including easier cleaning, productivity, powder quality, faster change-outs, reduced nozzle build up, reduced scorched particles along with long-term cost savings. Spray Nozzle Engineering are so confident with the longevity of CLICK&DRYTM products, that when operated within the terms of supply, they are the first in the world to offer a replacement guarantee on key components.

Entry level performance gains:

- Longer Run Times

- Reduced Scorched Particles

- Reduced Build Up Bearding

- Wider Spray Angles Possible

Find out more about CLICK&DRYTM

Bete spray drying nozzles

Spray drying is used by many industries to quickly and inexpensively transform food products, chemicals, and other products into dried powders. Powder is preferable because it has drastically reduced weight and increased storage life.

Spray drying can be accomplished across a range of powder production rates, from a few pounds per hour to over 100 tons per hour.

The basic process is to first concentrate the feed stock in a liquid form, atomise it at high pressure to create small droplets consisting of liquid and particles, then allow a hot gas to evaporate the liquid away leaving only the dry particulate.

The sprayed media feed stock can be a solution, slurry, paste, gel, suspension or a melt, as long as it has a solid component and a liquid component to carry the solids through the piping and then evaporate in the drying chamber. Any liquid that can be pumped can be spray dried, including feed stocks that are abrasive, corrosive, flammable, explosive, or toxic. Since the uses vary so much, a wide array of atomisers must be considered.

The function of a spray nozzle in a spray dry system is to control the feed stock flow rate and uniformly distribute atomised droplets/particles into the heated drying chamber.

Spray dry nozzles typically operate at higher pressures or utilise air-atomising techniques to produce droplets in the 30 – 120 micron range. This maximises the surface area to volume of the particles, allowing them to dry much quicker than other drying methods. In many dryers, evaporation is 95% complete within seconds.

BETE produces a variety of hydraulic and air-atomising nozzle types, features, and materials to fit your spray drying applications requirements.

Consistent performance and quality allow for the production of high quality products through constant particles sizes with even moisture content.

High strength, wear resistant, and high temperature material options allow for long service life and safe operation within the high pressure, high temperature, and abrasive applications found in the spray drying industry.

Common spray drying nozzle uses and industries:

- Food processing industry

- Chemical processing industry

- Manufacturing industry

- Pollution control industry

- Powdered cream/milk

- Powdered cheese

- Whey and protein

- Baby formula

- Instant coffee

- Plant proteins

- Eggs

- Yeasts

- Pet foods

- Vitamins

- Detergents

- Soaps

- Polycarbonate/polyvinyl

- Dyes

- Cellulose powders

- Metal powders

- Ceramic powders

The Benefits of a Professional Spray Drying Nozzle

A spray drying nozzle is an important piece of equipment for many powder industries.

Finding the right spray drying nozzle is a worthwhile investment of your time and can make a remarkable difference to everyday productivity. At Spray Nozzle Engineering, we make finding the right spray dryer nozzle easy for you, offering top quality nozzles at prices you can afford.

The Benefits of Spray Nozzle Engineering’s Click&Dry Spray Drying Nozzles

Our spray drying nozzles offer you an advantage that others simply won’t, for example:

- Durability: All our nozzles are extremely durable, holding up even among the worst conditions with longer life

- Increased Hygiene: As our spray drying nozzles are used in industries such as dairy, food service and pharmaceuticals, hygiene and cleanliness are our priority.

- Versatility: Our nozzles can be used across industries, and for a variety of purposes.

- Increased powder quality

- Low bearding and longer running

- Lower operating costs

What You Can Expect from Spray Nozzle Engineering when Purchasing a Spray Drying Nozzle

We stock quality Click&Dry spray dry nozzles and BETE nozzles. As Australia and New Zealand’s leading authority on industrial nozzle technology, you can expect such benefits as:

- Top Quality Customer Care: We always put you first and take great pride in our customer care.

- World Class Products: We source top of the line products from around the world, always making quality our priority.

- Accessibility: We know nozzles aren’t something everyone is extremely knowledgeable about, therefore, we make sure our information and products are as accessible as possible.

For over 30 years we have been New Zealand’s leading supplier of spray technology across industrial needs. Get in touch to find out more, or to order your nozzles.