When buying industrial nozzles for pulp and paper making, you may need to evaluate the cost of a nozzle change out, retrofit, or a new installation of spray bars. Selecting the right industrial nozzle can certainly contribute to slow nozzle change outs and impact production.

Paper mill manufacturers require shower nozzles that are easy to use and install, a change out system that could potentially save customers thousands of dollars in time and productivity. Operators should be able to change out multiple nozzles in a fraction of the time of conventional nozzle change out systems by holding ergonomic adjustment tools with just one hand.

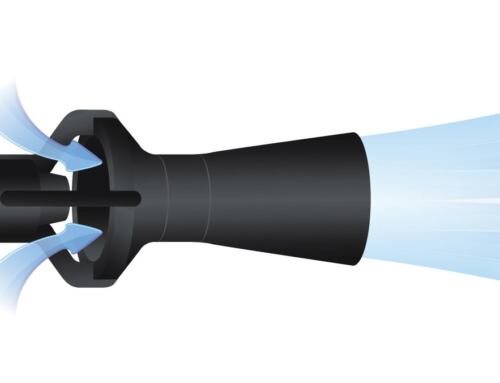

Other factors to consider when choosing shower nozzles, is having a system that eliminates incorrect alignment and safety hazards. Nozzles that use locating disc locks, align in the correct orientation every time, due to single direction rotation are a must.

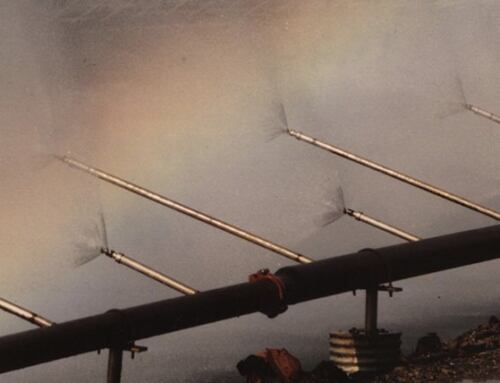

Spray Nozzle Engineering, serving the pulp, packaging, and fibre recycling industries for over 30 years, tackling all the industry concerns addressed above, by manufacturing and supplying the Snap Disc™shower nozzles.

Snap Disc™ nozzle’s secure alignment and quick release mechanism ensure consistent, and rapid change out performance on every spray nozzle. Encompassing a locating disc, flat flan or needle spray disc, gasket and weld base, in a large selection of pipe diameter fittings and seal options, the Snap Disc is the most comprehensive and biggest cost-saving shower nozzle change out system available.

Snap Disc, designed and made by Spray Nozzle Engineering for Australia, New Zealand international paper mills and OEM shower upgrades.