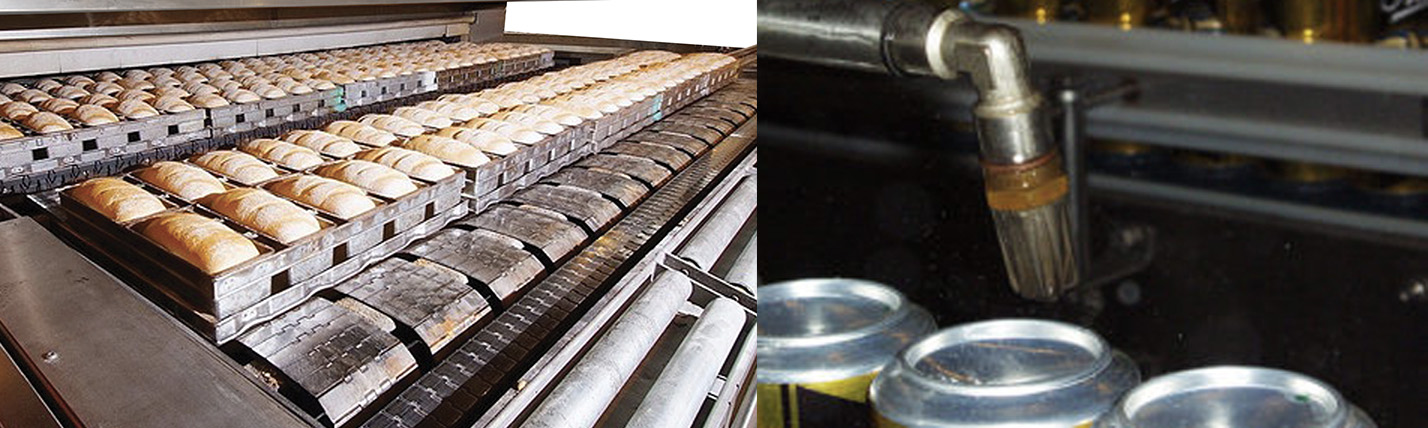

Offering total spraying solutions to the food and beverage industries

Spray Nozzle Engineering is Australia and New Zealand’s leading manufacturer and supplier of industrial spray technology, for applications including:

- coating – spraying

- cleaning – blowing

- drying – sorting

- mixing – cleaning

As well as unique washdown systems incorporating safer hose reels for safer hose handling solutions.

With a product for every process, Spray Nozzle assists customers in the food, beverage, dairy, spray drying, wine, brewing, dry goods and packaging industries; offering total spraying solutions for all your needs.

With offices in New Zealand and Australia, as well as distributors worldwide, the company provides technical development and a customer support team that can assist with both an engineered and patented product for even the most difficult or precision spraying solution in spray dry, tank cleaning, wash down and more with a focus in safety, hygiene, cost and time savings; innovative design and ergonomic features.

They have engineered patented products and represent world leaders as exclusive partners in fluid transfer and distribution, and safer compressed air nozzle and blow down applications. Saving water, energy, and costs whilst increasing safety and productivity.

Find below our large range of nozzles for the food and beverage processing:

Food and beverage nozzles enquire

-

The Strahman M-750 Hot & Cold Water Mixing Stations enable the operator to manually regulate water temperature as needed for the washdown application via independent controls. Model M-750 is the economical unit for washdown applications where the precise temperature of hot and cold water is not critical for the application. Manually turn the valves for a steady supply of water. A specially design blending chamber efficiently blends the hot and cold water for maximum performance. The M-750 mixing station is constructed from Stainless Steel with internal parts made of bronze/stainless steel and is equipped with a solid Stainless Steel hose rack for convenient hose storage. Hose and spray nozzle are sold separately. Available options include Wall Mounted (shown), Recessed Wall Box Units, and Pedestal Units.

-

The Strahman M-750TG Hot & Cold Water Mixing Station enables the operator to manually regulate water temperature as needed for the washdown application via independent controls. Model M-750TG is ideal for situations where the exact water temperature is crucial for the washdown application since it is equipped with a dial-type temperature gauge (TG) that indicates the wash water's exact temperature in both Celsius and Fahrenheit. Manually turn the valves for a steady supply of water to reach the right temperature. A specially design blending chamber efficiently blends the hot and cold water for maximum performance. The M-750TG mixing station is constructed from Stainless Steel with internal parts made of bronze/stainless steel and is equipped with a solid Stainless Steel hose rack for convenient hose storage. The hose and spray nozzle are sold separately. Available options include Wall Mounted (shown), Recessed Wall Box Units, and Pedestal Units.

-

Nozzle Features

- Internal mix

- Flow rates from 32 L/hr to 840 L/hr

- Very fine atomisation

-

Strahman swivel adapters in brass and stainless steel

Available swivels to keep your Strahman hoses and nozzles operating properly. -

Strahman swivel adapters in brass and stainless steel

Available swivels to keep your Strahman hoses and nozzles operating properly. -

Strahman swivel adapters in brass and stainless steel

Available swivels to keep your Strahman hoses and nozzles operating properly. -

Features:

- Water-saving trigger nozzles

- Heavy duty protective covers & bumpers

- Bronze & stainless steel construction

- Flat fan spray pattern

- Trigger controlled

- Optional swivel attachments available

-

BETE’s FlexFlow Spray Systems ensure precision control and flexible automation for our Hygienic Electric HydroPulse®, Industrial Electric HydroPulse, and other automatic spray nozzles. These plug-and-play controllers are an elegant solution for precision coating, moistening, and lubricating applications where intermittent spraying will improve accuracy and reduce waste. Consider the FlexFlow for any industrial process where expensive compounds or ingredients need to be sprayed directly onto the process target. Each control panel can be used as a standalone system – or upgrade to the 2000 model to integrate with your existing plant operations. Discover optimal spray performance for applying flavors, coatings, mold inhibitors, antimicrobials, preservatives, release agents, and moisturizers with exceptional accuracy.

-

The partnership of Spray Nozzle Engineering and Reel Tech gives you total fluid solutions. Our partnership allows us to supply safer and innovative CIP Tank cleaner and hose reel systems to meet the exact needs of the client. Our technology eliminates confined space entry hazards for personnel, manual handling of large and long lengths of CIP (Clean-in-place) hose, and fixed CIP Lances. Reel Tech Reels are designed with safer rewind speeds, explosion proof motors and can be integrated into PLC systems for fully automated washing. Our CIP rotating nozzles from SNE reduce CIP cycle times, water and chemical usage and turn around times, saving time and money whilst delivering safer cleaning solutions. Our reel technology also extends to bulk delivery-decanting and other food transfer and washdown applications requiring hose storage solutions.

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Rinse using a powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume "flooding spray"

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with a dedicated rinse hose (#914125)

-

Nozzle Features

- Designed to foam and rinse medium to large surfaces and objects using 2 different chemicals or 2 concentrations of the same chemical

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast, efficient coverage

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Quick disconnects allow the hose to be easily removed from the production floor when not in use

- Rinse at full pressure using the powerful 4-hole nozzle

- Stainless steel and polypropylene components ensure years of trouble-free performance

-

Nozzle Features

- Designed for precision foam application, and to rinse and sanitize medium to large surfaces and objects

- Projects a low volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle (up to 9' range)

- Covers up to 500 sq ft (46.5 sq m) in 4.5 minutes

- Adjustable foam consistency (wet/dry)

- Foam, rinse, and sanitize with one quick-connect hose

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, heavy spray

- Rinse using the fan pattern foam/sanitize wand, or connect the unique and powerful 4-hole rinse nozzle

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available as a portable unit (#913855)

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Foam, rinse, and sanitize with one quick-connect hose

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, heavy spray

- Rinse using the fan pattern foam/sanitize wands, or connect the unique and powerful 4-hole rinse nozzle

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with 3 separate hoses for incompatible chemicals (#914225)

-

Nozzle Features

- Designed to foam and sanitize large surfaces and objects

- Projects a high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 15' range)

- Covers up to 1000 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available with a lower volume of foam (#915120)

-

Nozzle Features

- Designed to foam, rinse and sanitize large areas and objects

- Projects a high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 15' range)

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Optional 0º nozzle for up to 25' range

- Adjustable foam consistency (wet/dry)

- Rinse using the unique and powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray"

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with lower volume foam output (#915125)

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Rinse using a dedicated hose and powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume "flooding spray"

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with stainless steel bodies (#915125SS)

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Foam & Sanitize with one hose (second hose available)

- Rinse using a dedicated hose and powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume "flooding spray"

- All stainless steel and polypropylene components ensure years of trouble-free performance

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- Foam and sanitize with one hose (second hose available)

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available with stainless steel bodies (#914120)

- Available with separate foam/sanitize hoses (#914122)

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with a lower sanitizer flow rate (#915220)

-

Nozzle Features

- Creates a high-volume, flooding spray

- Dilutes concentrated sanitisers to the lean ratios required for no-rinse applications in food plants

- Projects a high-volume flooding spray in a fan pattern for complete coverage

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with lower flow rates for slower applications (#973650, 973750)

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- 2 separate, colour-coded hoses for incompatible foaming and sanitizing chemicals

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene components ensure years of trouble-free performance

- Available with one hose (#915120)

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available with a lower sanitizer flow rate (#914220)

-

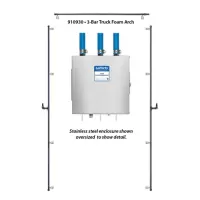

Nozzle Features

- Dilutes chemical concentrate at the unit independently for each foam bar

- Creates rich, clinging foam which increases chemical contact time and effectiveness

- Foam consistency (wet/dry) is adjusted with a single air regulator

- Top foam bar provides 8-10 ft. coverage

- Side foam bars provide 11-13.5 ft. coverage

- Unique stainless steel Spreader Nozzles™ project a wide foam pattern

- Rotate Spreader Nozzles™ inward to focus the foam output or outward for maximum coverage

- Chemical-resistant wetted components ensure durability and years of reliable performance

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

-

Nozzle Features

- Creates a high-volume, coarse spray

- Dilute concentrated sanitisers to the lean ratios required for no-rinse applications in food plants

- Projects a high-volume flooding spray in a fan pattern for complete coverage

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with a higher flow rate for even leaner dilution ratios (#973750)

-

Nozzle Features

- Designed to foam and sanitize medium to large areas

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available with a higher sanitizer flow rate (#915120)

-

Nozzle Features

- No compressed air is required

- Designed for foaming, rinsing and sanitizing medium to large surfaces

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 6' (depending on water pressure)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding" spray in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available without a rinse function (#915920)

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Rinse at full pressure using the powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray"

- Stainless steel and polypropylene components ensure years of trouble-free performance

- Available with a higher sanitizer flow rate (#915125)

-

Nozzle Features

- Designed for precision foam application, and to rinse and sanitize medium to large surfaces and objects

- Projects a low volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle (up to 9' range)

- Covers up to 500 sq ft (46.5 sq m) in 4.5 minutes

- Adjustable foam consistency (wet/dry)

- Rinse at full pressure using the powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray"

- Stainless steel and polypropylene components ensure years of trouble-free performance

- Available with a higher volume foam output (#915225)

-

Nozzle Features

- Designed to foam, rinse and sanitize medium to large surfaces and objects

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Rinse at full pressure using the powerful 4-hole nozzle

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray"

- Stainless steel and polypropylene components ensure years of trouble-free performance

- Available with a higher sanitizer flow rate (#914125)

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Available with a higher sanitizer flow rate to create even leaner ratios (#914120)

-

Nozzle Features

- Creates a high-volume, heavy spray

- Dilutes concentrated sanitisers to the lean ratios required for no-rinse applications in food plants

- Projects a high-volume flooding spray in a fan pattern

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with a higher flow rate for even leaner dilution ratios (#973850)

-

Nozzle Features

- No compressed air is required

- Designed for foam cleaning medium to large-sized areas

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan nozzle for fast coverage at distances up to 10' and zero-degree nozzle for up to 12' foam throw (depending on water pressure)

- Stainless steel components ensure years of outstanding performance with minimal maintenance

- Available for 2 chemicals (#917907)

-

Nozzle Features

- No compressed air is required

- Designed for foam cleaning small to medium-sized areas

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 6' (depending on water pressure)

- Chemical-resistant components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Use it where 35-125 PSI water is available

- Available with a higher flow rate (#970550)

-

Nozzle Features

- No compressed air is required

- Designed for foam cleaning medium to large-sized areas

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 10' (depending on water pressure)

- Chemical-resistant components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available as a portable system with a stainless-steel cart assembly (#912910)

-

Nozzle Features

- No compressed air is required

- Achieve strong chemical concentrations up to 4:1

- Weaker dilution ratios controlled by precision metering tips

- Designed for foam cleaning medium to large-sized areas

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 10' (depending on water pressure)

- Stainless steel components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available for standard concentrations (#912905)

-

Nozzle Features

- No compressed air is required

- Designed for foam cleaning medium to large areas

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 8' (depending on water pressure)

- Chemical-resistant components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Use it where 35-125 PSI water is available

- Available with a lower flow rate (#970525)

- Available for two chemicals (#970552)

-

Nozzle Features

- Designed to foam, rinse and foam medium to large surfaces and objects

- Two independent foamer bodies for separate foaming chemicals

- Quick-connect hose can be moved between foamer bodies

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Adjustable foam consistency (wet/dry)

- Rinse using the trigger gun with an adjustable cone/stream spray pattern

- All stainless steel components ensure durability and years of trouble-free performance

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces and objects

- Two independent foamer bodies for separate foaming chemicals

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a "flooding spray" for full coverage

- Sanitize using the trigger gun with an adjustable cone/stream spray pattern

- All stainless steel components ensure durability and years of trouble-free performance

- Available with a rinse function (#912127QD)

-

Nozzle Features

- Can be supplied with various other BETE nozzles for any desired application

- Flow rates from 28.1 L/Min to 290 L/min

- Clog resistant

- Spherical omnidirectional coverage

-

Nozzle Features

- Foamer creates rich, wet foam to increase chemical contact time and effectiveness

- Low volume foam and spray output (less than 1 GPM)

- Foam provides visual confirmation of complete coverage

- Projects foam up to 7' (depending on water pressure)

- The stainless steel quick disconnect socket features 6 retaining balls to lock the bottle assembly securely in place

- Quick disconnect the foam assembly to rinse

- Quick connect the sprayer assembly to create a fan pattern liquid spray

- Light, 32 oz bottles reduce wrist and arm fatigue and the risk of repetitive strain injuries

- No moving parts! Venturi action dilutes chemicals consistently

- Durable! Foamer and injector bodies are machined in the USA, not moulded

- Outlasts and outperforms similar moulded plastic products

- Color-coded lids help identify equipment and chemicals to enhance user safety

- No wetted brass components for optimal chemical resistance

-

Nozzle Features

- Foamer creates rich, wet foam to increase chemical contact time and effectiveness

- Foam provides visual confirmation of complete coverage

- Projects foam up to 12' (depending on water pressure)

- The stainless steel quick disconnect socket features 6 retaining balls to lock the bottle assembly securely in place

- Quick disconnect the foam assembly to rinse

- Quick connect the sprayer assembly to create a fan pattern liquid spray

- Light, 32 oz bottles reduce wrist and arm fatigue and the risk of repetitive strain injuries

- No moving parts! Venturi action dilutes chemicals consistently

- Great performance with water pressure as low as 20 PSI

- Durable! Foamer and injector bodies are machined in the USA, not moulded

- Outlasts and outperforms similar moulded plastic products

- Color-coded lids help identify equipment and chemicals to enhance user safety

- No wetted brass components for optimal chemical resistance

-

Nozzle Features

- Portable hose-end fogger makes it easy to fog hard-to-reach areas

- Easy to use! Just fill the bottle and press the thumb gun activator

- Atomizes and sprays chemical solutions using the included electric air compressor

- Low volume output is ideal for precise chemical application and fogging in small areas

- Venturi action draws pre-diluted chemicals from the Compact Fogger bottle

- Projects up to 15'

- Damp fog (mist) fills the air and covers exposed surfaces with chemicals, including hard-to-reach areas

- Metering tips can reduce chemical usage and output wetness

- Lightweight 32 oz bottle reduces wrist and arm fatigue as well as the risk of repetitive strain injuries

- Chemical-resistant components ensure durability and years of outstanding performance

- Lid colour options help identify equipment to enhance safety (blue standard - red, yellow, or green optional)

- Available with stainless steel cart and on-board bulk chemical storage (#950730)

-

Nozzle Features

- 315 Sanitiser accurately dilutes concentrated sanitisers using precision metering tips and can achieve the lean ratios required for no-rinse applications in food plants

- Sanitizer discharge quickly connects to the spray arm for CIP cleaning or the hand-held wand for manual spray sanitizing

- The fully-adjustable spray arm accommodates many conveyor belt positions — horizontal, vertical, angled, side-by-side, etc.

- Unique Spreader Nozzle™ projects a wide spray pattern

- 28" overhead distance = 48" wide coverage

- Coverage width increases with distance

- Each Spreader Nozzle™ can also be rotated 360° to spray at any angle for wider coverage or to hit hard-to-reach locations

- The spray arm can be permanently or temporarily mounted

- Manual sanitize wand projects a high-volume flooding spray in a fan pattern for complete coverage

- Machined stainless steel and polypropylene components ensure durability and years of outstanding performance

- Industrial-strength design holds up in tough environments

- Available as a foamer (#975930)

- Lafferty also manufactures portable Conveyor-Mate™ systems (#975912)

-

Nozzle Features

- HV Foamer accurately dilutes chemical concentrate on demand using precision metering tips

- The Foamer discharge hose quickly connects to the foam bar for CIP cleaning or the hand-held wand for manual foaming

- Accommodates many conveyor belt positions — horizontal, vertical, angled, side-by-side, etc.

- Two unique Spreader Nozzles™ project a wide foam pattern

- 36" overhead distance = up to 120" wide coverage

- Rotate the Spreader Nozzles™ inward to focus foam output

- 48" narrowest possible coverage

- Use the foam wand for manual cleaning

- Fan pattern nozzle covers up to 500 sq ft (46.5 sq m) in 1 minute and projects foam up to 15'

- Zero-degree nozzle for up to 25' range

- Adjustable foam consistency (wet/dry)

- Foaming expands the chemical and discourages over-application by providing visual assurance of coverage

- Rich, clinging foam increases chemical contact time and effectiveness

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Machined stainless steel and polypropylene components ensure durability and years of outstanding performance

- Industrial-strength design holds up in tough environments

- Available with a single Spreader Nozzle (#975930)

- Lafferty also manufactures portable Conveyor-Mate™ systems (#975932)

-

Nozzle Features

- LC Foamer accurately dilutes chemical concentrate on demand using precision metering tips

- The Foamer discharge hose quickly connects to the foam arm for CIP cleaning or the hand-held wand for manual foaming

- The fully-adjustable foam arm accommodates many conveyor belt positions — horizontal, vertical, angled, etc.

- Unique Spreader Nozzle™ projects a wide foam pattern

- 12" overhead distance = 30" wide coverage

- 24" overhead distance = 48" wide coverage

- Spreader Nozzles™ can also be rotated 360° to project foam at any angle for wider coverage or to foam hard-to-reach locations

- The foam arm can be permanently or temporarily mounted

- Manual foam wand fan nozzle covers up to 500 sq ft (46.5 sq m) in 2 minutes (up to 12' range)

- Foaming expands the chemical and discourages over-application by providing visual assurance of coverage

- Rich, clinging foam increases chemical contact time and effectiveness

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Machined stainless steel and polypropylene components ensure durability and years of outstanding performance

- Industrial-strength design holds up in tough environments

- Available with a lower flow rate for slower and/or narrower belts (#975910)

- Lafferty also manufactures portable Conveyor-Mate™ systems (#975932)

-

Nozzle Features

- LV Foamer accurately dilutes chemical concentrate on demand using precision metering tips

- The Foamer discharge hose quickly connects to the foam arm for CIP cleaning or the hand-held wand for manual foaming

- The fully-adjustable foam arm accommodates many conveyor belt positions — horizontal, vertical, angled, etc.

- Unique Spreader Nozzle™ projects a wide foam pattern

- 6" overhead distance = 12" wide coverage

- 12" overhead distance = 20" wide coverage

- 24" overhead distance = 32" wide coverage

- Spreader Nozzles™ can also be rotated 360° to project foam at any angle for the best coverage

- The foam arm can be permanently or temporarily mounted

- Low Volume output reduces water and chemical waste

- Manual foam wand fan nozzle covers up to 500 sq ft (46.5 sq m) in 4.5 minutes (up to 9' range)

- The foam expands the chemical, increases chemical contact time and effectiveness, and provides visual assurance of coverage that discourages over-application

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Machined stainless steel and polypropylene components ensure durability and years of outstanding performance

- Industrial-strength design holds up in tough environments

- Available with a higher flow rate for faster and/or wider belts (#975930)

- Lafferty also manufactures portable Conveyor-Mate™ systems (#975922)

-

Nozzle Features

- Screws into, and dispenses directly from, chemical concentrate drums for increased efficiency

- Equipped with both fine and coarse threads

- Machined stainless steel foamer body for maximum chemical and temperature resistance

- Designed for foam cleaning medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern nozzle for quick coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available as a wall-mounted unit (#915105)