When deciding what fire protection nozzles to be used for road tunnels and other fixed suppression installations in marine, offshore and in the petroleum field, it’s important to consider factors such as the flow rate, the kind of fire, type of fluid either if its foam, vapour or water, the environment that it’s in, and if someone has control of the flow or if it’s predetermined.

There are five major categories of nozzles for fire protection:

- Solid stream

- Fixed or single flow rate nozzle: This the most simple form of fire nozzle. It provides flow at a predetermined rate that cannot be altered while in use.

- Variable or adjustable flow rate nozzle: This nozzle allows the operator to manually select a desired gallonage while in use.

- Automatic or constant pressure nozzle: Designed to maintain a relatively constant pressure over a wide range of flows.

- Multi-purpose nozzle: This is a mix of solid hollow cone and fog nozzle, providing maximum reach and heat absorption. This industrial nozzle can be well suited for multiple applications including indoors, outdoors, high-rise, Compressed Air Foam System (CAFS), cooling and ventilation.

Australian and New Zealand manufacturers offer hundreds of models and type of industrial nozzles for fire protection. There are even customised nozzles that are tailored to effectively perform essential functions including controlling the flow of water or foam, giving reach to get to the fire from a safe distance, and shaping the flow for maximum effectiveness.

But how to choose the right industrial nozzle for a specific application? Spray Nozzle Engineering, a leader supplier of BETE nozzles for the Australasia fire protection industry, has put together a selection of the best high-performance nozzles for fire suppression:

Fire suppression Nozzles |

Design Features |

Application |

AFF – FM – Approved Flat Fan Fire Protection and (Extra) Wide Angle

|

|

It can be employed in water wall applications where water is used as a barrier to provide a protective shield against radiant heat, harmful gases and flames, and in water deluge applications for surface or equipment protection when relying on rundown. |

CW Nozzles – Full cone and hollow cone |

|

|

N series |

|

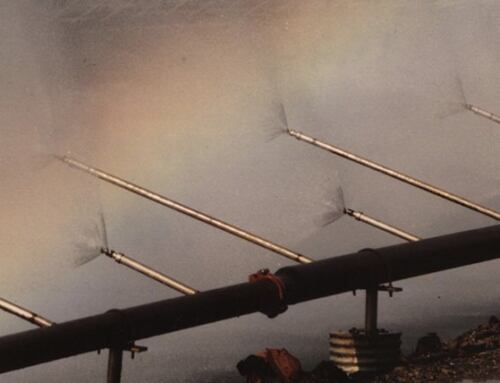

N series spiral nozzles are ideal for many road tunnel Fixed Fire-Fighting Systems (FFFS). The N spiral nozzles were put into real test in the 2007 Burnley tunnel fire in Melbourne, Australia. The N spiral nozzles contributed to minimal infrastructure damage and the rapid reopening of the tunnel. |

TF series |

|

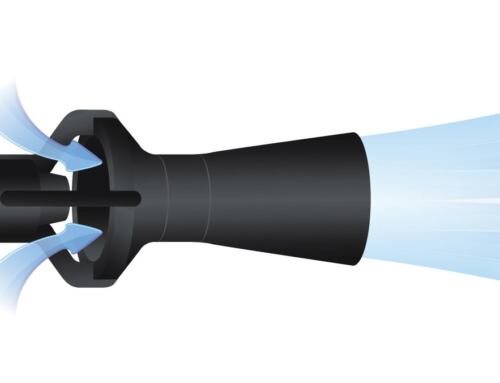

BETE’s original spiral full cone design has been proven to provide an ideal spray pattern for outdoor fire protection by providing a mix of coarser droplets ideal for drift resistance encapsulating and projecting smaller droplets ideal for cooling and suppression to the target area |

Maxi-Pass |

|

BETE’s unique, clog resistant S-vane design gives the MaxiPass the largest free passage available for a given flow rate, making it resistant to clogging, efficient, and reliable |

BETE offers a variety of industrial nozzles for open-type deluge, water walls, and water mist fire protection systems. They are proven to work in the most demanding environments and are trusted to protect offshore drilling and production platforms, petroleum storage and transfer stations, LNG tanks, refineries, and other valuable industrial complexes and equipment.

Many of BETE’s wide range of fire protection nozzles are tested and approved by rigorous third party systems, such as Factory Mutual (FM), Underwriters Laboratories (UL), Lloyd’s Register, and the U.S. Coast Guard to ensure they are manufactured and perform to the highest standards.

Spray Nozzle Engineering also supplies a large range of water monitors and cannons as well as patented vehicle fire protection nozzles such as the BM nozzles, designed to provide consistent spray distribution and fire suppression performance.