Skip to content

-

Nozzle Features

- Achieves strong chemical concentrations up to 2.8 to 1

- Weaker dilution ratios controlled by precision metering tips

- Projects a high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- 60-gallon chemical concentrate tank reduces downtime for refilling trips to the chemical room

- Designed for foam cleaning large areas and equipment

- Fan pattern nozzle for fast coverage (up to 15' range)

- Zero-degree nozzle for up to 25' range

- Adjustable foam consistency (wet/dry)

- Chemical-resistant components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available as a wall-mounted unit (#916115)

-

Nozzle Features

- Projects an incredibly high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- 60-gallon chemical concentrate tank reduces downtime for refilling trips to the chemical room

- Zero-degree foam nozzle projects foam up to 40' for cleaning very large areas, equipment and high ceilings without ladders or lifts

- Covers up to 500 sq ft (46.5 sq m) in 40 seconds

- Fan nozzle for broad coverage

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with a 20-gallon tank (#912020)

-

Nozzle Features

- Projects a very high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- 60-gallon chemical concentrate tank reduces downtime for refilling trips to the chemical room

- Open flow foam nozzle projects foam up to 45' for cleaning very large areas, equipment and high ceilings without ladders or lifts

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available as a wall-mounted unit (#916250)

-

Nozzle Features

- Creates a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Designed to apply 2 separate chemicals or 2 different concentrations on the same chemical

- Chemicals can be applied separately or simultaneously by adjusting the ball valves

- Fan pattern nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Chemical resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available for 1 chemical (#975805)

-

Nozzle Features

- This complete system includes all required components - just connect high pressure water and chemical

- chemicals from onboard containers and accurately dilutes to the required ratio

- Switch between soap and disinfectant, or two different concentrations of the same chemical

- Use the airless foam wand to project wet, clinging foam

- No compressed air required

- Foam increases chemical contact time and effectiveness, and provides visual confirmation of coverage

- Use the fan pattern foam nozzle for area coverage or zero degrees foam nozzle for increased range (up to 25')

- Foam throw distance and coverage varies based on incoming water pressure

- Quick connect the fan pattern spray nozzle for sanitizing and general cleaning without foam

- Open the chemical injector bypass valve to rinse at full volume and pressure

- Use the focused rinse nozzle for powerful blasting

- Rinse at a higher volume through the spray nozzle

- Industrial-strength stainless steel construction stands up to tough conditions and constant use - Built to last!

- Pressure gauge facilitates setup and metering tip selection

-

Nozzle Features

- This complete system includes all required components - just connect high-pressure water and chemical

- Draws chemicals from onboard containers and accurately dilutes to the required ratio

- Switch between soap and disinfectant, or two different concentrations of the same chemical

- Use the airless foam wand to project wet, clinging foam

- No compressed air is required

- Foam increases chemical contact time and effectiveness, and provides visual confirmation of coverage

- Use the fan pattern foam nozzle for area coverage or zero degrees foam nozzle for increased range (up to 25')

- Foam throw distance and coverage varies based on incoming water pressure

- Quick connect the fan pattern spray nozzle for sanitizing and general cleaning without foam

- Open the chemical injector bypass valve to rinse at full volume and pressure

- Use the focused rinse nozzle for powerful blasting

- Rinse at a higher volume through the spray nozzle

- Industrial-strength stainless steel construction stands up to tough conditions and constant use - Built to last!

- Pressure gauge facilitates setup and metering tip selection

-

Nozzle Features

- Foam and rinse through a single hose

- Designed for foaming and rinsing medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available as a wall-mounted unit (#915118)

-

Nozzle Features

- Designed to foam and sanitize medium to large surfaces

- Projects rich, clinging foam that increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Optional zero-degree nozzle for increased range

- Adjustable foam consistency (wet/dry)

- Sanitize using a dedicated hose, trigger gun & fan nozzle

- Stainless steel components ensure durability and years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available as a wall-mounted unit (#918120)

-

Nozzle Features

- Receives ready-to-use chemical solution from a central chemical feed system

- Creates a 1.7 GPM @ 40 PSI chemical spray

- Designed for spraying down any sized area or object

- Fan pattern nozzle for fast coverage

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with higher flow rates upon request

- Available with trigger gun discharge (#919158)

- Available as a pump-fed foamer (#920105)

-

Nozzle Features

- Receives ready-to-use chemical solution from a central chemical feed system

- Creates a 1.7 GPM @ 40 PSI chemical spray

- Trigger gun activation prevents the unit from running unattended

- Designed for spraying down any sized area or object

- Fan pattern nozzle for fast coverage

- Heavy-duty trigger gun with stainless steel internal components, easy-pull trigger, and insulated comfort grip with hand guard

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available with higher flow rates upon request

- Available with a ball valve discharge (#919155)

-

Nozzle Features

- No compressed air is required

- Designed for foaming & rinsing medium-sized surfaces where compressed air is not available

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan nozzle for fast foam coverage at distances up to 10' and zero-degree nozzle for up to 12' foam throw (depending on water pressure)

- All stainless steel components ensure durability and years of trouble-free performance

- Available without the rinse function (#917905)

-

Nozzle Features

- No compressed air is required

- Designed for foaming & rinsing medium to large surfaces

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 6' (depending on water pressure)

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#970525)

-

Nozzle Features

- No compressed air is required

- Designed for foaming & rinsing medium to large surfaces

- Projects wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 10' (depending on water pressure)

- Rinse using the trigger gun with an adjustable cone/stream spray pattern

- All stainless steel components ensure durability and years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#912905)

-

Nozzle Features

- Designed for foaming & rinsing medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 1 minute

- Adjustable foam consistency (wet/dry)

- Rinse using the trigger gun with an adjustable cone/stream spray pattern

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#912105)

-

Nozzle Features

- Designed for foaming & rinsing medium to large surfaces

- Projects rich, clinging foam that increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Optional zero-degree nozzle for increased foam throw

- Adjustable foam consistency (wet/dry)

- Rinse at full pressure with a dedicated hose & trigger gun

- Stainless steel components ensure durability and years of trouble-free performance

- Available without a rinse function (#918115)

- Available with a higher flow rate (#917118)

-

Nozzle Features

- Designed for foaming & rinsing medium to large surfaces

- Projects a substantial volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 13' range)

- Covers up to 500 sq ft (46.5 sq m) in 1.5 minutes

- Optional zero-degree nozzle for increased foam throw

- Adjustable foam consistency (wet/dry)

- Rinse at full pressure through the trigger gun

- Stainless steel components ensure durability and years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#917115)

-

Nozzle Features

- Designed for foaming & rinsing medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#915105)

-

Nozzle Features

- Foam and rinse through separate hoses

- Designed for foam cleaning medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Stainless steel and polypropylene wetted components of trouble-free performance

- Industrial-strength design holds up in tough environments

- Available without a rinse function (#914105-G)

-

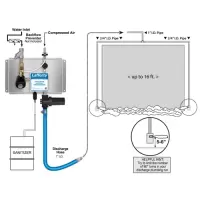

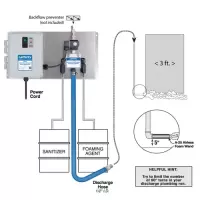

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for larger doors (#976651, 976652)

-

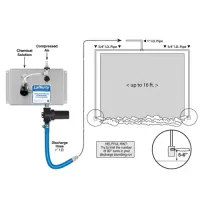

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 8'-16' wide/overhead doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique HV Spreader™ nozzles lay a foam pattern 8'-16' across and up to 10' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for smaller doors (#976650, 976651)

-

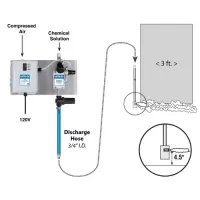

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for smaller and larger doors (#976650, 976652)

-

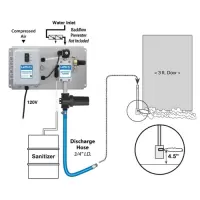

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- Fed with ready-to-use chemical solution from a central chemical pumping system

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for larger doors (#976641, 976642)

-

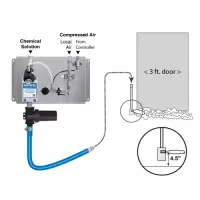

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Fed with ready-to-use chemical solution from a central chemical pumping system

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for smaller and larger doors (#976640, 976642)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 8'-16' wide/overhead doors

- Fed with ready-to-use chemical solution from a central chemical pumping system

- The two unique HV Spreader™ nozzles lay a combined foam pattern 8'-16' across and up to 10' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated and operated by compressed air from the Satellite Controller - no electrical connection is required at the entryway door.

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Choice of two Satellite Controllers:

- Timed Entryway Satellite Controller - An adjustable recycle timer applies foam at regular, timed intervals.

- PLC Jazz Entryway Satellite Controller - A pre-programmed PLC Controller allows variable settings for hours of operation and peak traffic demands.

- Available for smaller doors (#976640, 976641)

-

Nozzle Features

- Can be permanently mounted or moved for use in multiple locations

- Atomizes and sprays chemical solutions using only compressed air

- Venturi action draws pre-diluted chemicals from a nearby container

- Projects up to 6' in 4 directions

- Low volume output is ideal for fogging in small areas

- Damp fog (mist) fills the air and covers exposed surfaces with chemicals, including hard-to-reach areas

- Optional metering tips can reduce chemical usage and output wetness

- Chemical-resistant polypropylene construction ensures durability and years of outstanding performance

-

Nozzle Features

- Projects an incredibly high volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Open flow foam nozzle projects foam up to 45' for cleaning very large areas, equipment and high ceilings without ladders or lifts

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

- Available as a 60-gallon portable (#916960)

-

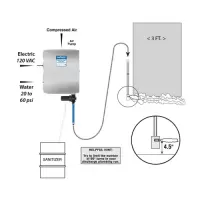

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- A cost-effective Flojet AODD pump draws water from an internal float tank to create the water pressure needed to drive the venturi injector

- Draws chemical concentrate from any nearby container

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

-

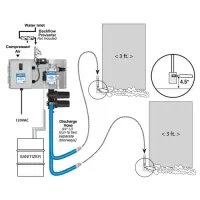

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- A cost-effective Flojet AODD pump draws water from an internal float tank to create the water pressure needed to drive the venturi injector

- Draws chemical concentrate from any nearby container

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitiser

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

-

Nozzle Features

- No compressed air is required

- Applies a layer of wet, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double door entryways to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Dilutes chemical concentrate "on the fly" from a container near the unit

- Dual chemical pickups allow for the addition of a foaming agent to the chemical solution to create richer foam

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for smaller doors (#976490)

- Available for 24VAC electric (#976495-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for two adjacent 3' wide employee walk doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for 24VAC electric (#976505-24V)

-

Nozzle Features

- No compressed air is required

- Applies a layer of wet, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Dilutes chemical concentrate "on the fly" from a container near the unit

- Dual chemical pickups allow for the addition of a foaming agent to the chemical solution to create richer foam

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for larger or dual doors (#976495)

- Available for 24VAC electric (#976490-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for larger doors (#976530, 976560)

- Available for 24VAC electric (#976500-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 8'-16' wide overhead doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique Spreader™ nozzles lay a foam pattern 8'-16' across and up to 10' wide to ensure that all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for smaller doors (#976500, 976530)

- Available for 24VAC electric (#976560-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Dilutes chemical concentrate "on the fly" from a container near the unit

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for smaller and larger doors (#976500, 976560)

- Available for 24VAC electric (#976530-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- Receives pre-diluted chemical solution from a user-supplied central chemical feed system

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for larger doors (#976256, 976260)

- Available for 24VAC electric (#976250-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Receives pre-diluted chemical solution from a user-supplied central chemical feed system

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for smaller & larger doors (#976250, 976260)

- Available for 24VAC electric (#976250-24V)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Receives pre-diluted chemical solution from a user-supplied central chemical feed system

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- The adjustable timer controls the application of foam at regular intervals - up to 1-minute foaming and up to 1 hour off

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Available for smaller & larger doors (#976250, 976260)

- Available for 24VAC electric (#976250-24V)

-

Nozzle Features

- Designed to apply 2-foaming chemicals and 1-sanitizing chemical on medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern foam nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Dilutes concentrated sanitizers to the lean ratios required for no-rinse applications in food plants

- Sanitizer is projected as a high-volume, "flooding spray" in a fan pattern for complete coverage

- All stainless steel and polypropylene wetted components ensure years of trouble-free performance

-

Nozzle Features

- Designed for foam cleaning medium to large surfaces

- Projects a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern nozzle for quick coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Industrial-strength design holds up in tough environments

-

Nozzle Features

- No compressed air is required

- Designed to apply 2 separate chemicals or 2 different concentrations of the same chemical

- Chemicals can be applied separately or simultaneously by adjusting the ball valves

- The unique machined polypropylene uni-body design is both compact and cost-effective

- Designed for foam cleaning small to medium-sized areas

- Projects a medium volume of wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 6' (depending on water pressure)

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Use it where 35-125 PSI water is available

- Available for just one chemical (#975075)

-

Nozzle Features

- No compressed air is required

- The unique machined polypropylene uni-body design is both compact and cost-effective

- Designed for precision foam application around sensitive equipment and close-range foaming

- Projects a very low volume of wet, clinging foam increasing chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Adjustable fan pattern nozzle for wide coverage or longer foam throw

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Use it where 50-125 PSI water is available

- Similar model is available with a higher flow rate (#975075)

-

Nozzle Features

- No compressed air is required

- The unique machined polypropylene uni-body design is both compact and cost-effective

- Designed for foam cleaning small to medium-sized areas

- Projects a medium volume of wet, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Projects foam up to 6' (depending on water pressure)

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Use it where 35-125 PSI water is available

- Available with a higher flow rate (#975085)

-

Nozzle Features

- Compact and cost-effective machined solid polypropylene uni-body design

- Easy to transport, install and uninstall

- Ideal for demonstrating different methods of chemical application to help decide which type of equipment is ideal for a particular situation

- Creates a medium volume of rich, clinging foam with compressed air

- Creates a medium volume of wet, clinging foam without compressed air

- Creates a fan pattern spray for non-foaming chemicals without compressed air

- Quick disconnects on all wands the user to easily switch between air-assisted foaming, airless foaming, and spraying

- Dilution ratios controlled with precision metering tips

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting - very useful for teaching equipment operation

- Machined foamer body, not moulded - Built to last!

-

Nozzle Features

- The unique machined polypropylene uni-body design is both compact and cost-effective

- Designed for foam cleaning medium to large surfaces

- Creates a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern nozzle for fast coverage (up to 12' range)

- Covers up to 500 sq ft (46.5 sq m) in 2 minutes

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Available with a lower flow rate (#975545-G)

-

Nozzle Features

- Compact and cost-effective machined solid polypropylene uni-body design

- Designed for cleaning small areas, around sensitive equipment or for close-range foaming

- Creates a low volume of rich, clinging foam which increases chemical contact time and effectiveness

- Fan pattern nozzle for quick, precise coverage with little over-spray (up to 9' range)

- Covers up to 500 sq ft (46.5 sq m) in 4.5 minutes

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Dilution ratios controlled with precision metering tips

- Machined foamer body, not moulded - Built to last!

- Available with higher volume output (#975555-G)

-

Nozzle Features

- The unique machined polypropylene uni-body design is both compact and cost-effective

- Designed for foam cleaning medium to large surfaces

- Creates a medium volume of rich, clinging foam which increases chemical contact time and effectiveness

- Foaming expands the chemical and reduces over-application by providing visual assurance of coverage

- Fan pattern nozzle for fast coverage (up to 14' range)

- Covers up to 500 sq ft (46.5 sq m) in 1.5 minutes

- Adjustable foam consistency (wet/dry)

- Water and air pressure gauges eliminate guessing to reduce set-up time and help with troubleshooting

- Chemical-resistant wetted components ensure years of outstanding performance with minimal maintenance

- Available with lower volume output (#975555-G)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 3' wide employee walk doors

- Fed with ready-to-use chemical solution from a central chemical pumping system

- The unique Spreader™ nozzle lays a foam pattern 3' across and 4' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated by compressed air from the Vision Satellite Controller - no electrical connection is required at the entryway door.

- Each Vision Satellite Foamer requires a separate direct connection to compressed air for foamer operation

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Used in conjunction with a 6-Zone PLC Vision Entryway Satellite Controller (#976710):

- Allows variable settings for holidays, weekly or seasonal changes hours of operation, and peak traffic demands

- Controls up to 6 satellite zones simultaneously, with up to 10 Vision Pump Fed Satellites per zone.

- Each zone is programmed independently

- Available for larger doors (#976725, 976726)

-

Nozzle Features

- Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

- Designed for 6' wide double doors

- Fed with ready-to-use chemical solution from a central chemical pumping system

- The unique MV Spreader™ nozzle lays a foam pattern 6' across and 6' wide to ensure all foot traffic and cartwheels are fully exposed to the sanitizer

- Automatic activation and shutoff for use in moderate to high-traffic areas

- Activated by compressed air from the Vision Satellite Controller - no electrical connection is required at the entryway door.

- Each Vision Satellite Foamer requires a separate direct connection to compressed air for foamer operation

- Adjustable foam consistency (wet/dry)

- Chemical-resistant wetted components ensure durability and years of reliable service with minimal maintenance

- Used in conjunction with a 6-Zone PLC Vision Entryway Satellite Controller (#976710):

- Allows variable settings for holidays, weekly or seasonal changes hours of operation, and peak traffic demands

- Controls up to 6 satellite zones simultaneously, with up to 10 Vision Pump Fed Satellites per zone.

- Each zone is programmed independently

- Available for smaller and larger doors (#976724, 976726)

Page load link