Clean empty your barrels from the Top

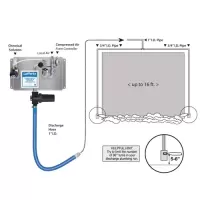

The new All-In-One Cleaning Machine combines high-performance impingement cleaning with integrated

vacuum extraction, which now allows all shapes and sizes of tanks without drains to be easily cleaned and emptied from the top.

The All-In-One features rotary impingement cleaning technology for exceptional performance, along with an integrated vacuum extractor which removes the cleaning liquid from within the vessel. The lightweight, hand-held machine is designed for operation at flow rates as low as 11.35 lpm. And, unlike other machines, the unit applies 100% of the water flow to cleaning - not in powering the unit itself. With a single insertion of the easily handled unit, 100% cleaning effectiveness along with completer liquid extraction, is assured.

As its name implies, the new All-In-One includes everything needed to easily clean and empty drain-less containers. No other cleaning method provides the convenience, power and low flow capabilities of the All-In-One.