For over 30 years Wilger has been developing innovative spray application components that make spraying safer, easier and more effective. Wilger Industries Ltd.

In 1985 Wilger designed and began manufacturing a multi-spray head turret, followed shortly by the Radialock cap and the COMBO-JET all-in-one Tip-Cap with snap-in strainer nozzle. This fully integrated nozzle cap and tip made nozzle cleaning and changing easier and safer; without the need to remove gloves.

Since then Wilger has gone on to pioneer drift reduction nozzle technology for all applications and sprayer types. With the world leading pre-orifice technology, Wilger has a nozzle tip for every droplet range required to meet your exact drift reduction and sprayer speed application.

Recently Wilger added the latest in long lasting stainless steel spray boom tube assembly technology; with their quick-nut no-tool SST assembly system.

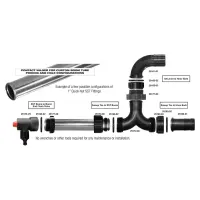

Starting with a robust fluid supply system is essential. The Quick Nut SST stainless tube boom sections are ready to assemble, with formed ends and punched nozzle body inlet holes. Add your choice of length and fittings, and you have a completely customised boom plumbing system.

Every part of your spray system is catered for by interchangeable components. Combo Rate saddles and nozzle bodies are “click and clamp” modules that are easy to assemble and can be stacked, allowing multiple nozzle bodies at the same location, operated individually or in combination with others to maximise coverage, with different flow rates and droplet sizes.

The Combo Rate Kwikstop shuts off sprayers faster to reduce application costs and crop damage by being mounted on top of the boom. In applications where sediment collecting at the bottom of the pipe is a consideration, the sediment is less likely to flow out and plug the nozzles or check valve.

Incorporating a Flow View visual indicator allows more effective monitoring. The Flow View ball flow indicators let you see the liquid flow when you can’t see the nozzles or outlets. Use as a manifold and monitor flow to multiple nozzles or outlets, in various branches of a liquid or air distribution system.

Work with Spray Nozzle Engineering to Find the Right Agriculture Spray Equipment

Spray Nozzle Engineering is your source for agricultural spray equipment from Wilger.

For more than 30 years, our business has been helping clients across a wide range of industries with their spraying equipment needs. One industry that has consistently relied on us for high quality spray equipment is agriculture. Farmers across New Zealand, Australia and beyond trust us to provide reliable and effective spray nozzles for pesticide application. We meet this market need by supplying the safest, most reliable and most technologically advanced pesticide nozzles in the world.

Common Mistakes People Make with Agriculture Spray Equipment

When it comes to purchasing spraying equipment—specifically sprayer nozzles—agricultural clients tend to make a few different mistakes. These include:

Not paying enough attention to the nozzle: Pesticide, weedicide and fertiliser spraying equipment is more than just a nozzle. The nozzle is one of the least expensive components of the sprayer, however without a reliable nozzle or the correct nozzle, the entire system can be compromised. It’s important to pay attention to nozzles when purchasing or upgrading pesticide applicator equipment.

Choosing the incorrect droplet size for the application: It is important to select the correct nozzle type for droplet size and improved spray drift control

Overlooking nozzle specs: Application rate, spray pressure, spray droplet size, amount of spray drift and width of sprayer boom are all variables that will change in pesticide application depending largely on the nozzle. Learning about the correct nozzle selection and design elements of spray nozzles will help you choose the one that will apply pesticide treatments most effectively, efficiently and safely.

Focusing on nozzles too much: As we’ve established, spray nozzles are important in the world of agricultural spray equipment. However, other parts of the applicator matter too, including body designs, nozzle fillers, boom spray mounting systems and more. At Spray Nozzle Engineering, we can help you find the right overall design for your pesticide applicator, to guarantee the best results across the board. We supply nozzle systems that take into account chemical handling safety.

Why Trust Spray Nozzle Engineering with Your Wilger Sprayer Nozzles Agricultural

Weedicide, fertiliser and pesticide application is a delicate but important process in most agricultural operations. You need equipment you can trust and rely on for this process. The question is, how can you know that you are getting what you need from Spray Nozzle Engineering:

Our experience: We have been involved in this industry for more than 30 years. We know the best brands, the best equipment and the top priorities for each industry when it comes to buying spraying equipment.

Our reputation: We are a trusted source for spray equipment and sprayer nozzles not just in the agricultural world, but also in other industries. These include food, beverage, mining, fire protection, packaging, petrochemical, pulp and paper, steel and more. Our glowing reputation in each of these industries should be proof that you can put your trust in our business.

Our focus on new technology: Spraying technology is improving all the time. In agriculture, these improvements are resulting in more accurate pesticide application, less material waste, easier operation of pesticide applicators and more. At Spray Nozzle Engineering, we are focused on keeping up with these new technologies and bringing them to our clients.

Don’t overlook nozzles or other crucial components of your pesticide, weedicide and fertiliser applicator system. Instead, stay ahead of the curve by working with Spray Nozzle Engineering to get the newest and best spray products on the market. Contact us today to learn more.